If you’re looking for the top professional frame joining machines for 2026, I recommend considering options like automatic CNC corner nailers, pneumatic machines with touch screens, and manual support tools for precision and versatility. These machines support various materials, sizes, and angles, ensuring durable, seamless joints. Whether for woodworking, framing, or industrial piping, the right equipment makes all the difference. Keep exploring, and you’ll discover the best options tailored to your needs.

Key Takeaways

- The list features top-rated professional frame joining machines with advanced CNC, pneumatic, manual, and plastic pipe welding capabilities.

- It includes equipment compatible with diverse materials like wood, foam, gypsum, and various plastics for versatile applications.

- Key features such as precision measurement systems, durable construction, and structural reinforcement ensure high-quality, reliable joints.

- The selection covers various machine types, from corner nailers and support tools to specialized pipe fusion welders, suitable for different professional needs.

- Detailed insights on price, support, and long-term durability help users choose the most efficient, cost-effective framing equipment for 2026.

| Automatic CNC Corner Nailer for Wood Framing |  | Innovative Automation | Power Source: Pneumatic (air-powered) | Nailing Capacity: Supports multiple nail sizes (5–15mm) | Corner Angles: Automatic 90° with adjustable options | VIEW LATEST PRICE | See Our Full Breakdown |

| INTSUPERMAI Picture Frame Nailer and Joiner Tool |  | User-Friendly Manual | Power Source: Manual (no power needed) | Nailing Capacity: Supports multiple nail sizes (7–15mm) | Corner Angles: Fixed 90° | VIEW LATEST PRICE | See Our Full Breakdown |

| INTSUPERMAI Pneumatic Corner Nailing Machine with Touch Screen |  | High-Speed Precision | Power Source: Pneumatic (air-powered) | Nailing Capacity: Handles 5–15mm V-nails | Corner Angles: Supports 90°, adjustable to 120°, 135° | VIEW LATEST PRICE | See Our Full Breakdown |

| 63-160mm 1850W Plastic Pipe Fusion Welder Tool |  | Industrial Strength | Power Source: Electric (110V, 220V) | Nailing Capacity: Supports various sizes (7–15mm) | Corner Angles: 90–135°, adjustable | VIEW LATEST PRICE | See Our Full Breakdown |

| Pneumatic Frame Corner Nailer for Photo Shops |  | Heavy-Duty Reliability | Power Source: Pneumatic (air-powered) | Nailing Capacity: Supports 5–15mm V-nails | Corner Angles: Supports 90°, 120°, 135° | VIEW LATEST PRICE | See Our Full Breakdown |

| Aluminum 5-Hole Corner Joining Plate for Construction |  | Budget-Conscious Choice | Power Source: Manual (air-pressure, no electricity) | Nailing Capacity: Supports 5–15mm V-nails | Corner Angles: Supports 90°, 120°, 135° | VIEW LATEST PRICE | See Our Full Breakdown |

| Automatic Pneumatic Corner Nailer for Frames |  | Advanced CNC Control | Power Source: Pneumatic (air-powered) | Nailing Capacity: Supports 5–15mm V-nails | Corner Angles: Supports 90°, 120°, 135° | VIEW LATEST PRICE | See Our Full Breakdown |

| Fletcher® U-200P Semi-Automatic Picture Frame Joining Machine |  | Semi-Automatic Efficiency | Power Source: Pneumatic (air-powered) | Nailing Capacity: Supports multiple sizes (7–15mm) | Corner Angles: Fixed 90°, with optional adjustable angles | VIEW LATEST PRICE | See Our Full Breakdown |

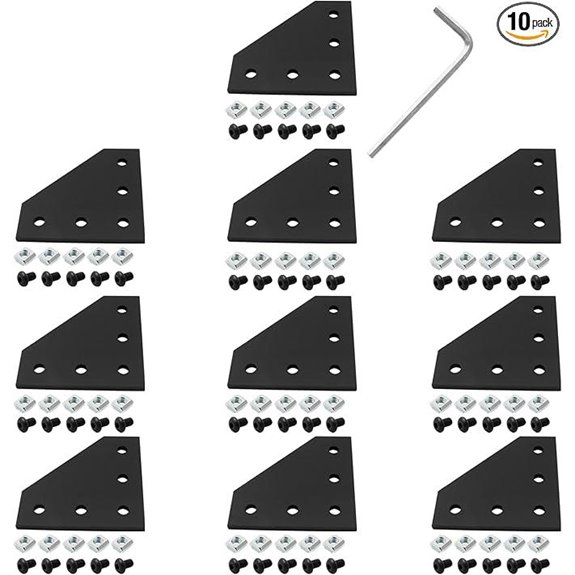

| 10 PCS Aluminum 2020 Corner Bracket Set |  | Versatile Compatibility | Power Source: Manual (no power or air needed) | Nailing Capacity: Supports 5–15mm V-nails | Corner Angles: Fixed 90° | VIEW LATEST PRICE | See Our Full Breakdown |

| Logan Pro-framing F300-1 Studio Joiner |  | Professional Industrial | Power Source: Manual (no power or air) | Nailing Capacity: Supports multiple nail sizes (7–15mm) | Corner Angles: Fixed 90°, some models support adjustable | VIEW LATEST PRICE | See Our Full Breakdown |

| Picture Framing Machine Nail Corner Joining Tool |  | Compact & Durable | Power Source: Manual (foot pedal, no power) | Nailing Capacity: Supports 7–15mm V-nails | Corner Angles: Fixed 90° | VIEW LATEST PRICE | See Our Full Breakdown |

| Universal 2D Frame Measuring System for Auto Body |  | Accurate Measurement | Power Source: Not specified (likely manual or mechanical) | Nailing Capacity: Supports various V-nail sizes (5–15mm) | Corner Angles: Fixed 90°, some models support adjustable | VIEW LATEST PRICE | See Our Full Breakdown |

| Smart Pneumatic Corner Nailing Machine with Touch Screen |  | Smart Digital System | Power Source: Pneumatic (air-powered) | Nailing Capacity: Supports 5–15mm V-nails | Corner Angles: Supports 90°, 120°, 135° | VIEW LATEST PRICE | See Our Full Breakdown |

| INTBUYING Manual Iron Frame Corner Joiner Machine |  | Easy Operation | Power Source: Manual (foot pedal, no power) | Nailing Capacity: Supports multiple nail sizes (7–15mm) | Corner Angles: Fixed 90° | VIEW LATEST PRICE | See Our Full Breakdown |

| Yokoma Nail Corner Framing Machine for Foam and Wood |  | Precision Construction | Power Source: Pneumatic (air-powered) | Nailing Capacity: Supports 5–15mm V-nails | Corner Angles: 90°, 120°, 135°, adjustable | VIEW LATEST PRICE | See Our Full Breakdown |

More Details on Our Top Picks

Automatic CNC Corner Nailer for Wood Framing

If you’re looking for a reliable and precise solution for wood framing, the Automatic CNC Corner Nailer stands out as an ideal choice. Its intelligent design features automatic angle cutting and seamless corner joining, making it perfect for various woodworking projects. The machine’s stable, widened frame and support plates provide enhanced durability, while four-sided clamping ensures accurate, explosion-free joints. With adjustable gears and flat-bottom nails, it adapts easily to different materials. The pneumatic system offers stable pressure and powerful performance, supporting continuous operation. User-friendly controls, alarms, and no calibration make this tool accessible for both professionals and hobbyists alike.

- Power Source:Pneumatic (air-powered)

- Nailing Capacity:Supports multiple nail sizes (5–15mm)

- Corner Angles:Automatic 90° with adjustable options

- Material Compatibility:Wood, foam, decorative lines

- Operation Type:Automated CNC control

- Additional Features:Touchpad control, stability

- Additional Feature:Integrated stability support plates

- Additional Feature:Touchpad intelligent control

- Additional Feature:Adjustable clamp gears

INTSUPERMAI Picture Frame Nailer and Joiner Tool

The INTSUPERMAI Picture Frame Nailer and Joiner Tool stands out for its manual, air-pressure-free operation, making it an ideal choice for small workshops and hobbyists who prioritize reliability and ease of use. Crafted from durable powder-coated steel and cast iron, it ensures longevity and stability. Its precise vertical and horizontal stops, along with front and rear shutters, guarantee accurate V-nail placement. It supports multiple nail sizes without changing dies—simply rotate the die wheel. Versatile for various materials like hardwood and foam, this compact tool delivers professional results with minimal maintenance, making it perfect for those seeking a dependable, straightforward framing solution.

- Power Source:Manual (no power needed)

- Nailing Capacity:Supports multiple nail sizes (7–15mm)

- Corner Angles:Fixed 90°

- Material Compatibility:Wood, foam, decorative materials

- Operation Type:Manual, hand-operated

- Additional Features:No power, precise positioning

- Additional Feature:Manual air-pressure operation

- Additional Feature:Compact small size

- Additional Feature:Multiple nails per position

INTSUPERMAI Pneumatic Corner Nailing Machine with Touch Screen

Designed for professional framing and woodworking enthusiasts, the INTSUPERMAI Pneumatic Corner Nailing Machine with Touch Screen stands out with its intuitive control system. I love how easy it is to set nail positions and quantities directly through the touch screen, making adjustments quick and hassle-free. The automatic clamping and 90-degree corner joining ensure precise, seamless frames every time. It handles various materials like solid wood, foam, and density board with ease, thanks to its dual pressure angle device. Powered by a reliable pneumatic system, it offers high-speed, continuous nailing, boosting productivity for workshops and hobbyists alike.

- Power Source:Pneumatic (air-powered)

- Nailing Capacity:Handles 5–15mm V-nails

- Corner Angles:Supports 90°, adjustable to 120°, 135°

- Material Compatibility:Wood, foam, density board

- Operation Type:Automated CNC control

- Additional Features:Touch screen, continuous nailing

- Additional Feature:Adjustable pressure 6-8kg/cm²

- Additional Feature:Supports various frame materials

- Additional Feature:High-speed continuous nailing

63-160mm 1850W Plastic Pipe Fusion Welder Tool

For professionals seeking a reliable and powerful solution for plastic pipe fusion, the 160mm 1850W Plastic Pipe Fusion Welder Tool stands out. It’s designed to efficiently join pipes from 63mm to 160mm, suitable for materials like PE, PB, PPR, PVDF, and PP. With an 1850W dual system—an 850W milling cutter and 1000W heating plate—it ensures fast heating and precise cutting. Built with durable materials, it offers stability, easy operation, and adjustable temperature from 32°F to 518°F. The machine’s robust frame and safety features make it ideal for industrial applications, providing consistent, high-quality welds for water supply, gas, and more.

- Power Source:Electric (110V, 220V)

- Nailing Capacity:Supports various sizes (7–15mm)

- Corner Angles:90–135°, adjustable

- Material Compatibility:PE, PPR, PVDF, PP pipes (not framing)

- Operation Type:Manual, industrial welding

- Additional Features:Welding, temperature control

- Additional Feature:Dual system: cutter & heater

- Additional Feature:Non-stick coated heating plate

- Additional Feature:Built-in safety holder

Pneumatic Frame Corner Nailer for Photo Shops

If you run a professional photo shop or framing workshop, the pneumatic frame corner nailer stands out as an essential tool for achieving perfect 90-degree joints quickly and reliably. Its heavy-duty all-metal frame and expansive worktable provide stability during nailing, supporting frame profiles up to 13 cm wide and 10 cm thick. Compatible with various V-nails and powered by an external air compressor, it features an intelligent touchscreen for setting nail position, count, and speed. The auto-clamping system ensures precise, seamless corners, making it ideal for fastening photo, picture, and specimen frames with strength and accuracy. This tool truly streamlines your framing process and guarantees professional results.

- Power Source:Pneumatic (air-powered)

- Nailing Capacity:Supports 5–15mm V-nails

- Corner Angles:Supports 90°, 120°, 135°

- Material Compatibility:Foam, MDF, hardwood, solid wood

- Operation Type:Pneumatic, semi-automatic

- Additional Features:Touchscreen, adjustable pressure

- Additional Feature:Supports angles 90°,120°,135°

- Additional Feature:Heavy-duty all-metal frame

- Additional Feature:39.4 x 20 worktable

Aluminum 5-Hole Corner Joining Plate for Construction

Looking for a reliable way to reinforce aluminum frame structures with precision and durability? The Aluminum 5-Hole Corner Joining Plate, model 3030L, is exactly what you need. Made from high-quality aluminum alloy, it offers corrosion resistance and long-lasting strength. Its five precisely positioned holes allow for flexible, secure connections at various angles. With dimensions ranging from 60mm to 120mm in length and a thickness of 4-6mm, it’s versatile for different projects like construction frames, 3D printers, and CNC machines. Each package includes four sleek, smooth plates, ensuring safe handling and an attractive finish. This plate combines durability, flexibility, and ease of use for demanding applications.

- Power Source:Manual (air-pressure, no electricity)

- Nailing Capacity:Supports 5–15mm V-nails

- Corner Angles:Supports 90°, 120°, 135°

- Material Compatibility:Wood, foam, MDF

- Operation Type:Manual, foot pedal

- Additional Features:Manual, simple operation

- Additional Feature:Corrosion-resistant anodized finish

- Additional Feature:Precise hole spacing

- Additional Feature:Multiple components included

Automatic Pneumatic Corner Nailer for Frames

The EQCOTWEA Intelligent Corner Nailing Machine stands out as an ideal choice for professionals who demand precise, seamless frame joints with minimal manual effort. Its automatic pneumatic design ensures accurate corner joining for picture frames, photo displays, and specimens. Supporting adjustable angles of 90°, 120°, and 135°, it handles frames up to 5.12 inches wide and 3.94 inches thick. The CNC touchscreen allows easy customization of nail position, quantity, and storage of up to 200 programs. With dual pressure devices and a seamless pressure system, it guarantees perfect 90° joints without manual calibration, preventing corner splitting on various materials.

- Power Source:Pneumatic (air-powered)

- Nailing Capacity:Supports 5–15mm V-nails

- Corner Angles:Supports 90°, 120°, 135°

- Material Compatibility:Wood, foam, MDF, various frame materials

- Operation Type:Automated CNC control

- Additional Features:Touchscreen, automatic clamping

- Additional Feature:Expandable worktable (~39.4” x 20”)

- Additional Feature:Dual pressure angle devices

- Additional Feature:Supports multiple nail sizes

Fletcher® U-200P Semi-Automatic Picture Frame Joining Machine

The Fletcher® U-200P Semi-Automatic Picture Frame Joining Machine stands out as an ideal choice for small to medium-sized custom and home frame shops that need precision and efficiency. This compact, well-built bench-top model features adjustable stops for V-Nail insertion, accommodating mouldings from 0.25” to 7.0” wide. Powered solely by compressed air, it requires no electrical hookup. Its dual-function pneumatic foot pedal allows quick, accurate nail placement and stacking, while magnetic hold-downs ensure precise alignment. With a small footprint and versatile components, it’s designed for reliable, trouble-free operation, making it a valuable addition to any framing setup.

- Power Source:Pneumatic (air-powered)

- Nailing Capacity:Supports multiple sizes (7–15mm)

- Corner Angles:Fixed 90°, with optional adjustable angles

- Material Compatibility:Wood, foam, decorative materials

- Operation Type:Semi-automatic, pneumatic

- Additional Features:Magnetic hold-down, quick change

- Additional Feature:Magnetic V-Nail holder

- Additional Feature:Quick-change profile stops

- Additional Feature:Dual-function pneumatic pedal

10 PCS Aluminum 2020 Corner Bracket Set

If you’re assembling professional-grade frames with 2020 aluminum extrusion profiles, the PCS Aluminum 2020 Corner Bracket Set is an excellent choice due to its robust construction and precise design. This set includes 10 anodized aluminum L-shaped brackets with a 5-hole pattern for secure connections. Made from 3.7mm thick alloy, these brackets provide exceptional strength and stability for your projects. The package also includes 50 M5 T-slot nuts, hex screws, and a wrench, making assembly straightforward. Perfect for CNC machines, 3D printers, or custom frames, these brackets ensure reliable, durable joints every time.

- Power Source:Manual (no power or air needed)

- Nailing Capacity:Supports 5–15mm V-nails

- Corner Angles:Fixed 90°

- Material Compatibility:Aluminum extrusions, various profiles

- Operation Type:Manual, foot pedal

- Additional Features:Compact, high precision

- Additional Feature:CNC crafted precision

- Additional Feature:Heavy-duty aluminum alloy

- Additional Feature:Multiple assembly components

Logan Pro-framing F300-1 Studio Joiner

For professional framers seeking perfect, permanent joints, the Logan Pro-framing F300-1 Studio Joiner stands out as a top choice. It delivers professional-quality wood frame molding joints that resemble frame shop results. Made in the USA, it features a magnetic nail holder supporting all v-nail sizes with quick depth adjustments for hard and soft woods. Compact at 9 x 3.7 x 11.4 inches and weighing just 8.64 pounds, it’s easy to handle. Rated 4.3 stars from 224 reviews, it’s highly regarded for durability and precision. No batteries are needed, and it offers a reliable 1-year warranty, making it suitable for both professionals and serious hobbyists.

- Power Source:Manual (no power or air)

- Nailing Capacity:Supports multiple nail sizes (7–15mm)

- Corner Angles:Fixed 90°, some models support adjustable

- Material Compatibility:Wood, MDF, decorative molding

- Operation Type:Manual, hand-fed

- Additional Features:Adjustable stops, quick change

- Additional Feature:USA-made quality

- Additional Feature:Supports all V-nail sizes

- Additional Feature:Quick depth adjustment

Picture Framing Machine Nail Corner Joining Tool

Designed with small workshops, hobbyists, and anyone needing precise corner joins in mind, the JARYANNIX Picture Framing Machine Nail Corner Joining Tool offers a compact yet powerful solution. It’s perfect for framing, wood corner joining, and molding. The tool features V-nails in sizes from 7 to 15mm, accommodating frame widths up to 150mm and thicknesses up to 100mm. Made of durable alloy steel and cast iron, it’s easy to install in limited space. The foot pedal operation makes it silent, safe, and simple to use, allowing me to quickly secure corners with multiple nails. It works on various materials, making it versatile for small-scale production.

- Power Source:Manual (foot pedal, no power)

- Nailing Capacity:Supports 7–15mm V-nails

- Corner Angles:Fixed 90°

- Material Compatibility:Wood, foam, MDF

- Operation Type:Manual, foot pedal

- Additional Features:Foot pedal, manual operation

- Additional Feature:Manual foot pedal operation

- Additional Feature:Magnetic support hardware

- Additional Feature:Multiple profile supports

Universal 2D Frame Measuring System for Auto Body

The Universal 2D Frame Measuring System for Auto Body stands out for its exceptional measurement precision, making it an ideal choice for auto body technicians and repair shops that demand accurate, reliable results. Crafted from high-quality aviation aluminum with an electrophoresis process, it offers durability, wear resistance, and rust prevention. Its high-precision structure ensures measurement errors stay within ±1mm, improving accuracy during vehicle repairs. The complete kit includes versatile scales, probes, and accessories, simplifying various measurement tasks. Lightweight and portable, it comes with a carrying case for easy transport. Plus, its user-friendly design and instructional videos enable quick setup and efficient operation, even for solo users.

- Power Source:Not specified (likely manual or mechanical)

- Nailing Capacity:Supports various V-nail sizes (5–15mm)

- Corner Angles:Fixed 90°, some models support adjustable

- Material Compatibility:Automotive parts, not framing

- Operation Type:Manual, measuring system

- Additional Features:Portable, high accuracy

- Additional Feature:High-precision ±1mm

- Additional Feature:Portable carrying case

- Additional Feature:Versatile measurement tools

Smart Pneumatic Corner Nailing Machine with Touch Screen

Equipped with a smart CNC touchscreen, the Smart Pneumatic Corner Nailing Machine guarantees precise, easy operation, making it an ideal choice for woodworking enthusiasts and professional shops aiming for high accuracy and efficiency. It supports multiple V-nail sizes and adjustable angles for 90°, 120°, and 135° corners, perfect for photo frames, shadow boxes, and custom projects. The system allows you to set nail position, quantity, speed, and frequency without complex calibration. Built with a reinforced all-metal frame and a stable pneumatic system, it assures reliable, heavy-duty performance. Its intelligent alarm system keeps operation smooth, making it a versatile, high-performance tool for demanding woodworking tasks.

- Power Source:Pneumatic (air-powered)

- Nailing Capacity:Supports 5–15mm V-nails

- Corner Angles:Supports 90°, 120°, 135°

- Material Compatibility:Wood, MDF, foam, decorative materials

- Operation Type:Automated CNC control

- Additional Features:Touchscreen, auto-clamping

- Additional Feature:Auto system memory

- Additional Feature:Dual-pressure angle device

- Additional Feature:Continuous punching capability

INTBUYING Manual Iron Frame Corner Joiner Machine

If you’re looking for a reliable, easy-to-operate corner joiner machine for small-scale framing projects, the INTBUYING Manual Iron Frame Corner Joiner Machine stands out as an excellent choice. Its vertical design guarantees precise corner joining with four nail heads for secure fastening. The lightweight yet durable structure, combined with electroplated parts and a sturdy tabletop, offers both stability and longevity. You can effortlessly change molds with the rotating die handwheel, and the foot pedal allows for quick, accurate operation. Plus, the extension table and compact size make it versatile and perfect for workshops with limited space, delivering professional results every time.

- Power Source:Manual (foot pedal, no power)

- Nailing Capacity:Supports multiple nail sizes (7–15mm)

- Corner Angles:Fixed 90°

- Material Compatibility:Wood, small profiles

- Operation Type:Manual, foot pedal

- Additional Features:Manual, quick setup

- Additional Feature:Easy mold change

- Additional Feature:Compact small footprint

- Additional Feature:Extension table support

Yokoma Nail Corner Framing Machine for Foam and Wood

For professionals seeking precise and versatile corner joining, the Yokoma Nail Corner Framing Machine stands out with its intelligent CNC control system and adjustable nailing angles. It features a 90-degree stapling angle and handles frame thicknesses up to 5.51 inches, making it perfect for foam, wood, and composite materials like gypsum and density board. Its automatic nail alarm, adjustable speed, and memory functions streamline workflow, while dual pressure clamps ensure stability. The machine supports various nail sizes and angles, providing flexibility for different projects. With robust construction and automated operation, it delivers consistent, high-quality joints for picture frames, cross-stitch frames, and more.

- Power Source:Pneumatic (air-powered)

- Nailing Capacity:Supports 5–15mm V-nails

- Corner Angles:90°, 120°, 135°, adjustable

- Material Compatibility:Foam, wood, composite materials

- Operation Type:Automated pneumatic control

- Additional Features:CNC, automatic operation

- Additional Feature:Adjustable pneumatic pressure

- Additional Feature:Supports multiple materials

- Additional Feature:Automated corner stability

Factors to Consider When Choosing a Professional Frame Joining Machine

When selecting a professional frame joining machine, I focus on factors like nailing precision and strength to guarantee durable results. I also consider material compatibility and ease of operation to match my specific needs. Additionally, I look at automation, control features, and build quality to find a reliable, long-lasting tool.

Nailing Precision and Strength

Achieving ideal nailing precision and strength is essential for creating durable, well-joined frames. Precise nailing ensures tight corner joints, minimizing gaps and misalignment that can compromise stability. Strong nailing penetration is crucial, especially when working with hardwoods or dense materials, to guarantee durability. Adjustable pressure settings allow me to optimize the nail force, reducing the risk of splitting or blowouts. Automated or CNC-controlled nailing processes are a game-changer, providing consistency and ensuring each joint meets strict strength standards. Additionally, the ability to accommodate various nail sizes and angles directly impacts the overall joint strength and versatility for different frame types. Prioritizing these factors helps me select a machine that delivers reliable, high-quality results every time.

Material Compatibility and Range

Choosing a frame joining machine that supports a wide range of materials is essential for versatile and efficient projects. I look for machines that can handle wood, foam, MDF, and density boards, ensuring I’m prepared for various framing tasks. It’s also important to check the maximum frame width and thickness the machine can handle so I don’t encounter limitations on larger projects. Compatibility with different nail or staple sizes, like 5mm to 15mm V-nails, adds flexibility for different joining needs. I also consider whether the machine features a pressure angle system that distributes force evenly across soft and hardwoods, preventing damage. Adjustable pneumatic pressure helps make certain of secure joints without compromising material integrity, making the machine adaptable to different materials and project demands.

Ease of Operation Features

Selecting a frame joining machine that’s easy to operate can substantially boost your efficiency and accuracy. I look for machines with intuitive control systems, like touchscreens or simple foot pedals, to make operation straightforward. Adjustable settings for nail position, quantity, and pressure are vital, as they help me handle different frame materials and sizes effortlessly. Automatic alignment features, such as corner clamps or stops, guarantee precise joints with minimal manual effort. I also value programmable nailing sequences or memory functions that speed up repetitive tasks. Safety features like clear alarms and accessible controls are essential to prevent errors and keep operations smooth. Overall, user-friendly features save time, reduce mistakes, and make my workflow more reliable and less stressful.

Automation and Control Systems

Automation and advanced control systems play a essential role in ensuring consistent, high-quality frame joints. I look for machines with CNC touchscreen controls that let me precisely set nail positions, quantities, and speeds, boosting efficiency. The ability to store multiple nailing programs is a big plus, especially for high-volume production. Automated pressure regulation and dual pressure angle devices help prevent corner splitting, ensuring each joint is reliable. Intelligent alarm systems integrated into the control panel are crucial—they notify me immediately of any issues, minimizing errors and downtime. I also value manual override options, giving me flexibility to adjust or bypass automation when needed. Overall, these features help me maintain high standards while streamlining the workflow.

Durability and Build Quality

When investing in a professional frame joining machine, durability and build quality are critical for guaranteeing long-term performance. I look for machines made from high-quality, wear-resistant materials like reinforced metal alloys or aircraft-grade aluminum, which resist fatigue and last through heavy use. Precise fabrication is essential, with smooth surfaces and minimal sharp edges to prevent injuries and ensure seamless assembly. Heavy-duty frames with reinforced supports and stable bases help maintain accuracy and reduce vibrations during operation. I also check for robust internal components, such as reinforced cylinders and high-strength screws, which ensure consistent performance over time. Additionally, proper sealing and protective coatings on critical parts prevent corrosion and damage from dust or moisture, extending the machine’s lifespan and maintaining its reliability.

Price and After-Sales Support

Considering the overall investment in a professional frame joining machine, it’s essential to evaluate not just the initial price but also the costs of accessories, upgrades, and maintenance down the line. A higher upfront cost might include better support or longer-lasting parts, saving you money later. Equally important is gauging the manufacturer’s after-sales support—look for technical assistance, training, and readily available replacement parts to minimize downtime. Check if the machine comes with a warranty, what it covers, and its duration to protect your investment. Also, consider the availability of local or online service centers for prompt repairs. Finally, review customer feedback to gauge the manufacturer’s support quality and responsiveness, ensuring you choose a reliable, well-supported machine.

Frequently Asked Questions

What Safety Features Do These Machines Typically Include?

These machines typically include safety features like emergency stop buttons, safety guards, and interlock systems to prevent accidental operation. I always check for clear visual warnings and automatic shutdown mechanisms that activate if something goes wrong. Safety sensors help detect obstructions, ensuring the machine only works when conditions are safe. Overall, these features safeguard operators from injuries and ensure safe, reliable operation in professional settings.

How Does Maintenance Vary Among Different Frame Joining Machines?

Maintenance methods differ quite a bit among frame joining machines. Some require routine checks, cleaning, and calibration, while others need specialized service for parts like welders or clamps. I find that regular inspections prevent major malfunctions, but advanced machines with high-tech features demand more meticulous upkeep. Staying proactive with maintenance ensures peak operation, reduces downtime, and extends the lifespan of your machine. Consistent care keeps your projects precise and productive.

Are There Specific Brands Known for Durability and Reliability?

I find that brands like Durafix, JET, and KUKA are known for their durability and reliability. These manufacturers have a solid reputation for producing sturdy, long-lasting machines that withstand heavy use. When I look for a frame joining machine, I prioritize these brands because they consistently deliver high-quality performance and require less maintenance over time. Choosing trusted brands gives me peace of mind and better results in my projects.

Can These Machines Be Customized for Unique Framing Projects?

Absolutely, these machines can be customized for your unique framing projects. I’ve found that most professional-grade machines offer versatile settings and adjustable features, allowing me to tailor the joins precisely to my needs. Some brands even provide optional accessories or software upgrades. While it might seem complex at first, I assure you, with a little guidance, customizing becomes straightforward, making your projects more efficient and perfectly suited to your creative vision.

What Is the Typical Learning Curve for New Operators?

The learning curve for new operators typically ranges from a few days to a few weeks, depending on their prior experience and the complexity of the machine. I find that hands-on training and detailed manuals help speed up the process. Most people get comfortable with basic functions quickly, but mastering advanced features may take a bit longer. Consistent practice and proper guidance are key to becoming proficient efficiently.

Conclusion

Choosing the right professional frame joining machine can truly transform your workflow. Each option offers unique features that could make or break your projects—will you prioritize precision, speed, or versatility? The best choice depends on your specific needs, but one thing’s for sure: the right machine could be the game-changer you’ve been waiting for. Ready to make that leap? The perfect tool might just be one decision away—are you prepared to find out?