Cleveland’s success with robotics shows how innovation and education work together to transform industries. The city invests in STEM programs, like the XRP initiative, and partners with local universities to develop a skilled workforce. Together, these efforts help industries adopt automation, making manufacturing safer, more efficient, and competitive. This synergy boosts local jobs and economic growth. If you want to see how Cleveland’s approach is shaping its bright future, keep exploring more details about their strategy.

Key Takeaways

- Cleveland’s educational initiatives, like XRP, integrate robotics with STEM, fostering a skilled future workforce.

- Industry partnerships with local universities accelerate adoption of automation and innovative manufacturing solutions.

- Robotics are vital in Cleveland’s manufacturing sectors, improving safety, efficiency, and competitiveness.

- Workforce development programs, including masterclasses, equip students and professionals with advanced robotics skills.

- The collaboration of education and industry drives Cleveland’s economic growth and positions it as a robotics innovation hub.

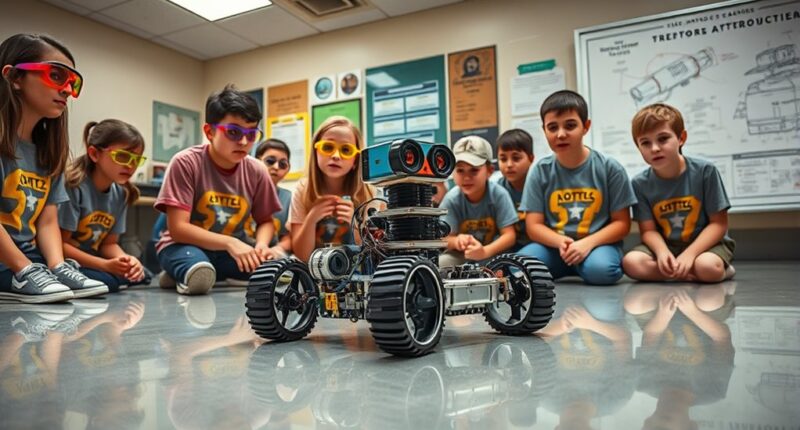

Cleveland is emerging as a leader in robotics innovation and education, transforming its manufacturing landscape and workforce development. You can see this shift through the city’s proactive initiatives aimed at preparing students and workers for the automation-driven future. In 2025, the Cleveland Metropolitan School District launched the Experiential Robotics Platform (XRP), a program designed to give students hands-on experience with robotics and AI. Over 1,000 robotics kits, valued below a textbook’s cost, were introduced into classrooms in the fall of that year. These kits aren’t just ordinary tools; they’re 3D printed through a Community Manufacturing Initiative using U.S.-assembled Prusa Core One printers at MAGNET. This approach keeps costs low and promotes local manufacturing, connecting education directly with industry practices. Accompanying the hardware is a masterclass series, offering students lifetime access to experts in additive manufacturing and 3D printing technology. This guarantees that students gain not only practical skills but also insights into the cutting-edge trends shaping future jobs. Such programs are supported by Cleveland’s focus on STEM education, which is crucial for developing a skilled workforce. Regular meditation practices foster inner peace and enhance happiness and well-being, aligning closely with Cleveland’s strong industrial base. The city maintains a competitive steel manufacturing sector where robotics are essential for tasks like cutting and welding, especially at companies like NUCOR Steel. Robotics help mitigate hazardous working conditions in high-temperature industries such as metal casting at General Aluminum. Meanwhile, automotive parts manufacturers like TRW Automotive rely heavily on robotics for forming, deburring, and polishing components. These technologies support the industry’s shift toward automation, filling labor shortages caused by changing workforce demographics and increasing technological demands. Firms like Robots.com, with two decades of experience, provide customized robotic solutions that keep Cleveland’s manufacturing sector competitive. You’ll also notice that Cleveland’s focus on robotics education and industry integration has a direct impact on the local economy and employment. As of mid-2025, the average robotics professional salary in Ohio is roughly $91,266 annually, with significant room for growth based on experience and specialization. Although the state’s robotics job market isn’t yet saturated, opportunities are expanding, especially as companies seek skilled workers to operate and maintain advanced automation systems. Ohio ranks 50th nationally in robotics salaries, signaling room for wage improvements but also highlighting the city’s potential to attract talent through ongoing investments and industry partnerships. Cleveland’s academic institutions play a crucial role in this transformation. Cleveland State University hosts research programs focused on controls, robotics, and automation, fostering innovation and supporting workforce development aligned with industry needs. These collaborations between universities and local firms accelerate the adoption of smart manufacturing technologies, positioning Cleveland as a hub for applied robotics. When you connect the city’s educational initiatives with its industrial strength, it’s clear Cleveland is creating a robust ecosystem that drives economic growth and technological leadership. This success story demonstrates what happens when innovation and education work hand in hand, shaping a resilient, future-ready manufacturing landscape.

Frequently Asked Questions

How Has Cleveland Funded Its Robotics Programs?

You find that Cleveland funds its robotics programs through diverse sources. Private foundations like the Thomas F. Peterson Charitable Trust and Malcolm E. Kenney Foundation provide substantial support, along with local and regional corporate sponsorships. Educational grants from organizations such as the Cleveland Foundation bolster STEM initiatives. Community partnerships and targeted fundraising efforts guarantee resources cover expenses like competition fees, robot parts, and outreach. All funds directly support student activities, fostering long-term growth and access across schools.

What Challenges Did Cleveland Face Implementing Robotics Education?

You face several challenges implementing robotics education in Cleveland. Recruiting and training enough qualified mentors is tough, and their workload can limit student support. Engaging students, especially underserved groups, requires targeted outreach and expanding programs. Securing consistent funding for equipment, training, and competitions remains difficult, while developing standardized curricula and teaching complex skills like programming and engineering demands ongoing innovation. Balancing these needs is essential to sustain and grow the program effectively.

Are There Partnerships With Local Industries or Companies?

Yes, Cleveland partners actively with local industries and robotics companies. You’ll see collaborations with firms like Big Sky Engineering, NewWay Automation, and Paragon Robotics, which provide tailored automation solutions to local manufacturing. Additionally, Cleveland Clinic’s research initiatives, like simVITRO, work closely with industry players. These partnerships foster innovation, improve manufacturing processes, and support workforce development, ensuring Cleveland remains a leader in robotics and industrial automation.

How Do Students Benefit Academically From Robotics Programs?

You’ll see a real boost in your academic performance through robotics programs, with students experiencing a 15% increase in STEM achievement. These programs enhance your understanding of math and science by applying concepts practically, making learning more engaging. You develop strong problem-solving and troubleshooting skills while working hands-on with robots. Additionally, robotics helps you grasp physics and programming better, leading to improved grades and a deeper interest in STEM subjects.

What Are Cleveland’s Future Plans for Robotics Expansion?

You should know Cleveland plans to expand its robotics programs by increasing access to low-cost 3D-printed kits in more schools, ensuring broader hands-on STEM learning. They aim to strengthen industry partnerships, integrate advanced manufacturing skills into education, and support more competitive robotics teams. The city also intends to scale up community engagement through events and mentorship, preparing students for future careers in automation, manufacturing, and tech, fostering a robust local talent pipeline.

Conclusion

As you see Cleveland’s robotics success unfold, it’s clear that when innovation meets education, the results are inspiring—like a spark igniting a bright future. This story shows that with the right support and creativity, you can turn ambitious ideas into reality. Keep pushing boundaries and embrace the power of learning and technology. Just like a well-oiled machine, your efforts can drive progress and spark change in your community, proving anything’s possible when you work together.