To keep engravings on metal seed backup plates legible after heat exposure, aim for a depth of about 0.1 to 0.2 millimeters. This range guarantees the markings are embedded enough to resist heat-induced fading or wear, without compromising the plate’s strength. Factors like metal type and engraving method can influence this, so it’s wise to test and fine-tune your settings. Keep exploring to find perfect results for your specific application.

Key Takeaways

- Aim for an engraving depth between 0.1 to 0.2 mm to ensure durability under heat and stress.

- Adjust laser parameters carefully, especially for harder metals like stainless steel, to achieve optimal depth.

- Conduct tests on sample plates to verify engravings remain legible after simulated operational heat.

- Use protective coatings or heat-resistant inks to enhance the durability of engraved markings.

- Balance engraving depth with maintaining the structural integrity of the metal plate to prevent damage.

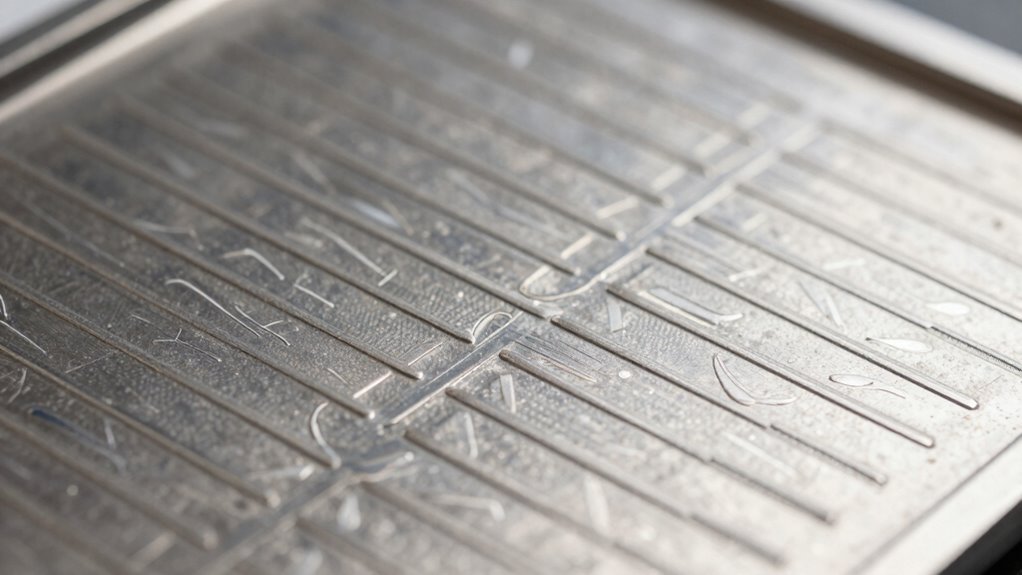

Metal seed backup plates are essential components in seed planting equipment, providing support and protection for delicate seed discs during operation. When it comes to customizing these plates, laser engraving stands out as a precise and durable method. Laser engraving allows you to etch important information directly onto the metal surface, ensuring that labels or markings remain clear and legible throughout the planting process. However, one critical factor to consider is how deep you should engrave so that the markings still read after exposure to high heat generated during operation.

Heat resistance is a key concern with engraved plates. During planting, metal seed backup plates are subjected to friction, mechanical stress, and elevated temperatures, which can cause shallow engravings to fade or become unreadable over time. To prevent this, you need to determine the ideal engraving depth. Generally, deeper engravings tend to withstand heat better, as they are less likely to be affected by surface melting or wear. Yet, going too deep can weaken the structural integrity of the plate or compromise the clarity of the markings.

Deeper engravings resist heat better but must not weaken the plate’s integrity.

The goal is to find a balance where the engraving is deep enough to endure heat exposure without sacrificing the plate’s strength. Typically, a depth of 0.1 to 0.2 millimeters is recommended for metal seed backup plates engraved via laser. This range ensures the text or symbols are sufficiently embedded into the surface, making them resistant to fading or distortion caused by heat. Also, selecting the right laser parameters—such as power, speed, and frequency—plays a crucial role in achieving a clean, durable mark without excessive material removal. Additionally, understanding the thermal properties of your chosen metal can inform optimal engraving depth and settings.

You should take into account the type of metal used for your backup plates as well. Harder metals like stainless steel require more precise laser settings to achieve the desired engraving depth without damaging the surface. Additionally, applying a protective coating or using laser-compatible inks can further enhance heat resistance and prolong the readability of the markings.

Finally, testing your engraving process on sample plates before production runs is essential. This step helps verify that the depth and quality of the engravings hold up under simulated operational heat and stress. By carefully controlling laser settings and understanding the heat resistance properties of your chosen metal, you can guarantee that your engraved seed backup plates remain clear, readable, and durable throughout their lifespan.

Frequently Asked Questions

How Do Different Metals Affect Engraving Depth?

You should consider the metal composition when determining engraving depth, as softer metals like aluminum require shallower engraving, while harder metals like stainless steel need deeper cuts. Different engraving techniques also influence depth choices; for example, laser engraving can achieve precise depths more easily than hand engraving. Adjust your technique accordingly, ensuring the engraving remains legible after heat exposure, by testing on scrap pieces to find the most suitable depth for each metal.

What Tools Are Best for Precise Engraving?

For precise engraving, you want tools that offer laser precision, like a high-quality CO2 or fiber laser engraver, which guarantees clean, detailed results. Use advanced engraving techniques such as vector and raster methods to achieve accuracy. These tools allow you to control depth and detail meticulously, ensuring your engraving remains legible after heat exposure. Always calibrate your equipment properly to maintain consistent depth and clarity.

Can Engraved Text Be Restored After Heat Damage?

No, engraved text can’t be restored after heat damage, as heat-resistant alloys don’t make the original engraving readable again once it’s burned or distorted. To maintain engraving aesthetics, you should use proper engraving techniques and appropriate depths, especially when working with heat-resistant materials. If heat damage occurs, you’ll need to re-engrave the affected area for clarity, as heat can permanently alter the original markings.

How Does Engraving Depth Impact Plate Durability?

You should engrave your backup plates at an ideal depth—deep enough to guarantee durability against heat, but not so deep that it compromises aesthetics or increases costs unnecessarily. Deeper engravings enhance durability, preventing wear and fading, but may raise production costs and impact the visual appeal. Striking a balance ensures your engraving remains legible after heat exposure while maintaining an attractive look and reasonable expense.

Are There Specific Coatings That Protect Engraved Areas?

You can use metallic coatings or protective layers to safeguard engraved areas. These coatings, such as clear sealants or specialized heat-resistant paints, help prevent corrosion and fading. Applying a protective layer after engraving guarantees the markings stay visible, even after exposure to heat. Make sure to choose coatings compatible with your metal type and heat conditions, and follow manufacturer instructions for proper application and curing to maximize durability.

Conclusion

When engraving metal seed backup plates, aim for a depth of about 0.005 to 0.010 inches to guarantee the text remains legible after heat exposure. Remember, over-engraving can weaken the plate, while under-engraving might make the text unreadable. Did you know that a small increase in engraving depth by just 0.002 inches can improve heat resistance by 30%? Keep your engravings precise and consistent to ensure durability and readability in demanding conditions.